Dynamic Compensation - Toward the Next-Generation Industrial Robot

Summary

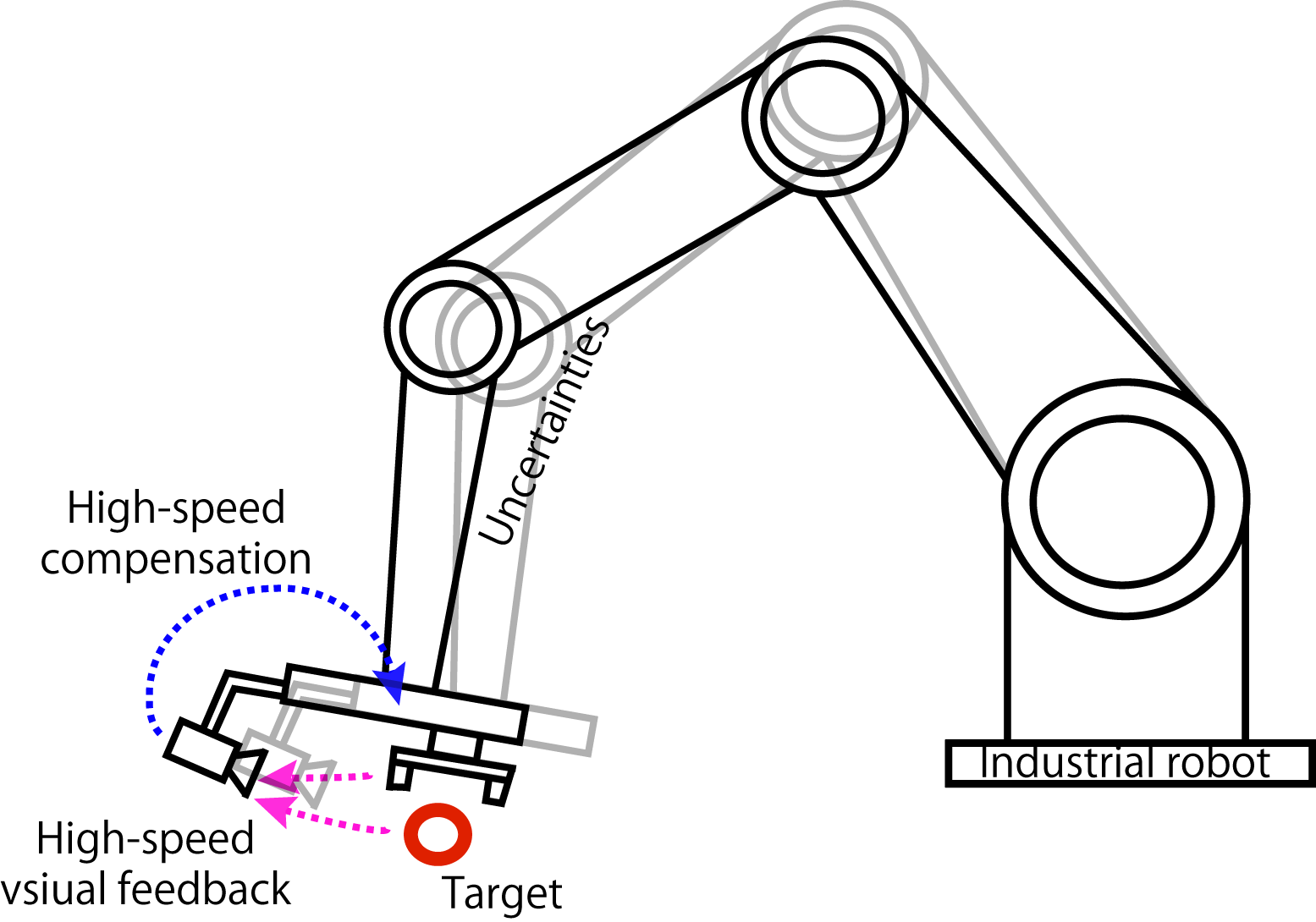

Traditionally it is difficult for industrial robots to achieve highs-speed motion with high accuracy due to large dynamical uncertainties. We present a solution using dynamic compensation by adopting high-speed vision and compensation actuators to compensate for the uncertainties caused by the system itself as well as the external environment. In this study, we present two application tasks: fast and accurate contour-tracking and high-speed peg-and-hole alignment, with a commercial industrial robot. Traditionally, the playback method is the most common approach to control an industrial robot. However, it is time-consuming and exhausting to teach an accurate path point by point. We propose to perform the 2D contour-tracking task by adding a high-speed robotic module under the dynamic compensation scheme. Through this method, a coarse global path can be easily taught with very few roughly chosen teaching points. The errors between the coarse path and the target path are then dynamically compensated by the high-speed robotic module under 1,000 fps visual feedback. As a result, accurate tracking for a target contour with random pattern is achieved with fast speed. The proposed method is also capable of compensation of external uncertainties. For example, the same tracking result can be obtained under unknown external disturbances. It should be noted that since the coarse motion is smooth with constant velocity, it is energy efficient for the industrial robot. The same technology is demonstrated with the task of high-speed peg-and-hole alignment. Here, we require the main robot to move at high-speed while the pose of the workpiece is uncertain. The coarse motion is roughly taught and can be random within a certain range of each hole. Letting the main robot perform the coarse motion, fast and accurate alignment is achieved through fine compensation by the high-speed robotic module.

This technology can improve existing industrial robots’ performance while at the same time reduce the workload of robot operators. It may find applications in many industrial tasks, such as in welding, painting as well as assembly.

Movie

If you want to use the original video, please send an e-mail for copyright permission to contact .