Dielectric Elastomer Based Laser Beam Pointing Method

Summary

Lasers and laser beam pointing methods are one of the key technologies used in our modern digital life. Advanced three-dimensional fabrication and manufacturing techniques is at the core of laser beam pointing technology. It allows the fabrication and manufacturing of complex items that would not be possible using previously available technologies. The market is growing, and the associated cost is decreasing as the technology becomes mature and patent-free such as 3D printing technology.

However, the accuracy is not good enough for more precise fabrication and manufacturing due to the mechanical error, such as screw and gear-teeth errors. The galvanometer scanning method is a typical mechanical movement, and the precision of these systems is limited because of backlash, accuracy of parts processing, etc. Furthermore, the above movement is based on angular control, so it is effective for wide-range scanning; however, its precision is inversely related to the distance between the laser projection system and the target. Hence, laser scanning technology should improve, in turn improving the accuracy for fabrication and manufacturing.

To solve the above two problems, we propose a laser scanning method using dielectric elastomer actuators (DEA) where the manipulation of the direction of the laser beam is controlled by the thickness of the DEA.

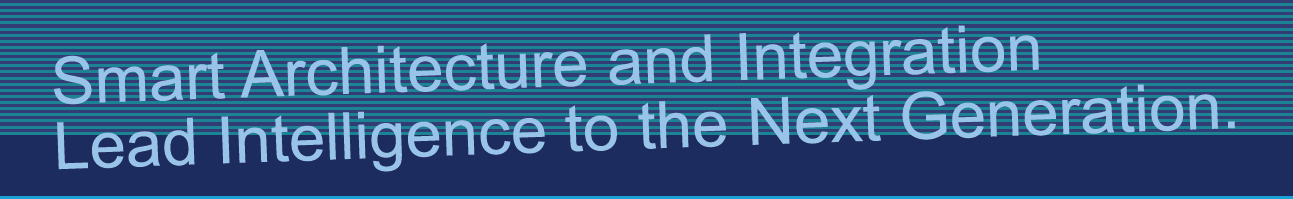

DEA-based laser scanning is based on Snell's law: the optical path undergoes a parallel shift when laser beams pass through a certain material. According to this principle, we formularized how the thickness of the transparent layer affects the point of laser projection. This change in optical path is based on the membrane thickness. DEA is a transparent and smart material that can transform electrical energy into mechanical movement. The thickness of DEA material can be controlled by varying the applied voltage, as it will be squeezed by electromechanical pressure.

We employed visible and ultraviolet laser beams to test our system. The experimental results demonstrated good transmittance for two laser candidates (Near to ultraviolet light ~ 405 nm wavelength and Visible light ~ 633 nm wavelength), and both achieved high-precision control at the micrometer level. Near to ultraviolet laser beams are required to congeal photosetting resin for stereolithography in 3D printing, therefore, our result can pioneer the use of DEA-based laser scanning for stereolithography.

|

| Figure1. Sketch showing the displacement shift when an incident ray passes through a DEA material without applied voltage (left), and that the scale of the displacement shift can be controlled by the applied voltage(right). |

|---|

|

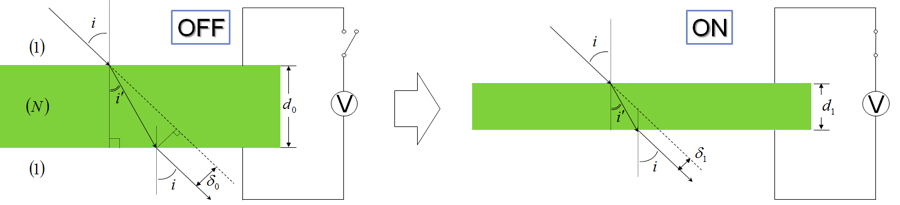

| Figure 2. Setup overview. The laser beam passes through the DEA membrane, projects onto paper, and is captured by a camera with a micro lens. |

|---|

References

- Tomohiko Hayakawa, Lihui Wang, Masatoshi Ishikawa, Dielectric elastomer-based laser beam pointing method with ultraviolet and visible wavelength , SPIE Photonics West 2016(San Francisco, California, USA. 2016.02.17)/ (Poster Session) [DOI:10.1117/12.2212081]