Active sensing using vibration with robot hand

Summary

In recent years, the demand for production using general-purpose

robots has increased in order to achieve high-mix low-volume

production. Because of this, the demand for automation of product

inspection has also increased. On the other hand, except for visual

inspection using cameras, dedicated machines are often used for

automatic product inspection.

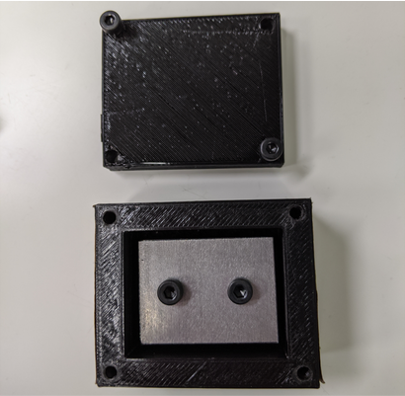

Therefore, in this research, we deal with the product inspection

using a general-purpose robot hand. Specifically, it deals with

vibration inspection that detects abnormalities inside the object

that cannot be detected by visual inspection. By using a

general-purpose robot hand for inspection, it is possible to detect

abnormalities in products during production work, which is thought

to lead to improved productivity.

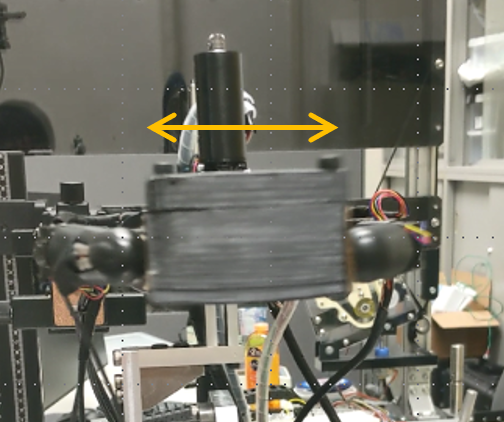

We propose the inspection method that a robot hand attached a 6-axis

force sensor to the fingertip grasps the object and applies

vibration. Then, by analyzing the time-series data of the force at

that time, the abnormality is detected. This time, evaluations are

done by ROC-AUC (Area Under the Receiver Operating Characteristic

Curve) for three features (the peak-to-peak value of the signal, the

peak-to-peak value of the filtered signal(80-1000 Hz bandpass

filter), and the power of high-frequecy vibration) of each axis. In

addition, the parameters of vibration are determined using the

Bayesian optimization method to improve detection accuracy.

We have conducted experiments and succeeded in inspecting the

looseness of bolts of objects fastened with bolts (in a place that

cannot be seen from the outside) and discriminating liquids with

different viscosities in containers that cannot be seen from the

outside.

Reference

- Fumiya Shimada, Kenichi Murakami, Taku Senoo, and Masatoshi Ishikawa, Bolt loosening detection using multi-purpose robot hand, The 2020 IEEE/ASME International Conference on Advanced Intelligent Mechatronics (AIM2020) (Boston, 2020.7.9 [online])/Proceedings, pp.1860-1866, (2020).