Variable Focus Microlens Array Based On Dielectric Elastomer Actuator

Summary

Adaptive lenses have variable focal length performance and have been studied for applications in imaging, optoelectronic, and biometrical devices. The adaptive lens mostly had been realized by controlling the curvature of the refractive surface of a liquid surface profile or an interface profile between two liquids, and the focusing point could be controlled by piezo actuator pumps, electrowetting phenomena, dielectrophoresis and some other ways. However, unlike the previous variable focus lenses who were filled with liquid, this research proposed a fabrication method on how to build a variable focus microlens array based on a dielectric elastomer actuator (DEA). The proposed lens array was functioned with the variable focal performance. The DEA material, who is a soft elastomer, serves as the lens material.

When a voltage was applied on the DEA elastomer, the electric field will arouse an effective compressive Maxwell stress across the elastomer. The electrostatic pressure will squeeze the DEA elastomer, result in decreasing in thickness and increasing in area. Two electrode plate with microlens array pattern was attached on top and bottom of the DEA elastomer, and connected with a programmable voltage supply. 40*40 mm square and 1 mm thickness acrylic elastomer (3M, VHB 4910) was employed as DEA material. Two electrodes (circular conductive stainless plates) with 30 mm in diameter and 1 mm thickness were placed on top and bottom of the DEA elastomer separately. Two electrodes were fixed in the holes of two insulate plastic plates (40*40 mm square, 1 mm thickness and 30 mm holes) in order to avoid electrical discharge. The electrode plates were fabricated with 9*9 lens array pattern, and each lens cell's aperture size was 1.5 mm in diameter. The electrode plates were pasted on the DEA elastomer firmly, so that when the active voltage was applied on the DEA elastomer, the electrodes can squeeze the elastomer and reshape the lens profile. The focal length of the lens cell will be changed by controlling the applied voltage.

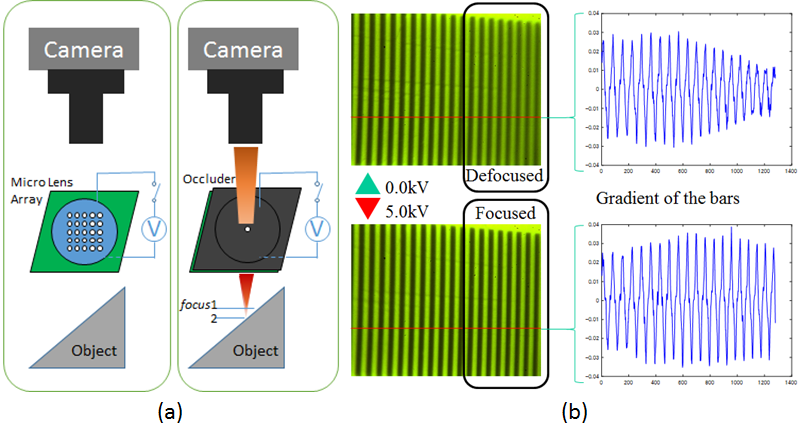

A target with depth information (Edmund Optics, DOF 5-15 Depth of Field Target) was placed behind the test microlens array prototype. A camera (Edmund Optics, EO-1312C, monochrome) was set in the opposite side, and a microlens kit (Edmund Optics, EO-39686 and EO-55359) was mounted on the camera for observation. In order to confirm the variable focus performance of a single lens cell, a black occluder with an aperture, that was a bit larger than the diameter of the microlens cell, was placed above the test prototype, as shown in the Fig.

|

| Figure 1. (a) A target with depth field information was observed by a camera with a micro lens mounted through the micro lens array prototype. A black occlude was employed so as to confirm the tunable performance of one lens cell. (b) The upper left image was captured when zero voltage was applied on the DEA, and while the lower left image was recorded when the applied voltage was 5 kV. The right side of the image was changed from defocus to focus, due to the focal length changing of the lens cell. . |

|---|

Movies

Focus was shifted from left to right by adding applied voltage, when the voltage was changed from 0.0 to 5.0 kV.

Reference

- Lihui Wang, Tomohiko Hayakawa, Masatoshi Ishikawa, Dielectric-elastomer-based fabrication method for varifocal microlens array, Optics Express, Vol.25, Issue 25, pp. 31708-31717 (2017)[PDF(3.3M)][DOI:10.1364/OE.25.031708]

- Lihui Wang, Tomohiko Hayakawa, and Masatoshi Ishikawa, A fabrication method for variable focus micro lens array based on deformation of dielectric elastomer actuator, European Optical Society Bi-Annual Meeting (EOSAM) 2016 (Berlin, Germany. 2016.09.28)/ (Oral Session)